Projects (including R&D)

-

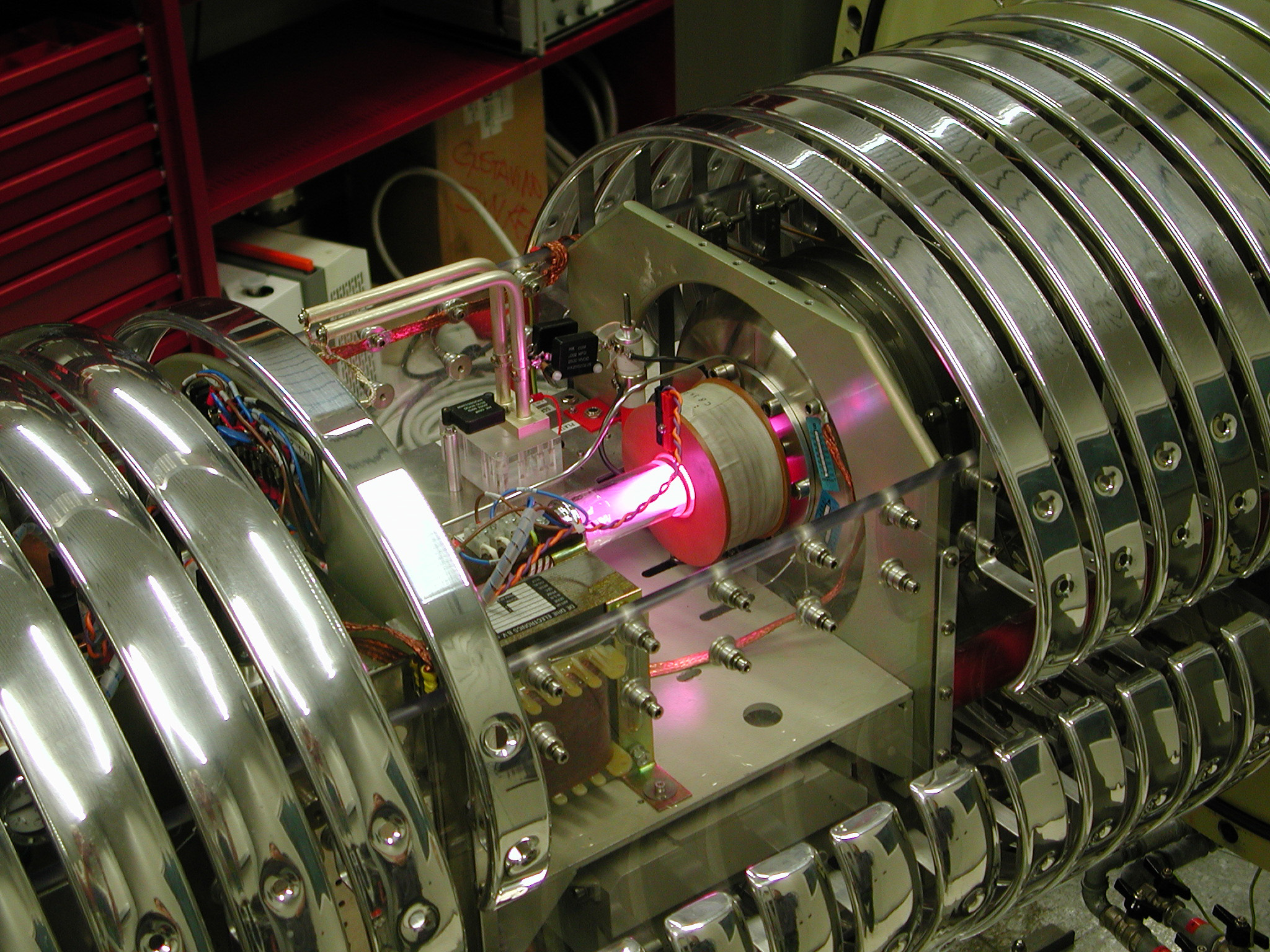

secondary emission tests for energy recovery in the production of neutral ion beams (in progress)

-

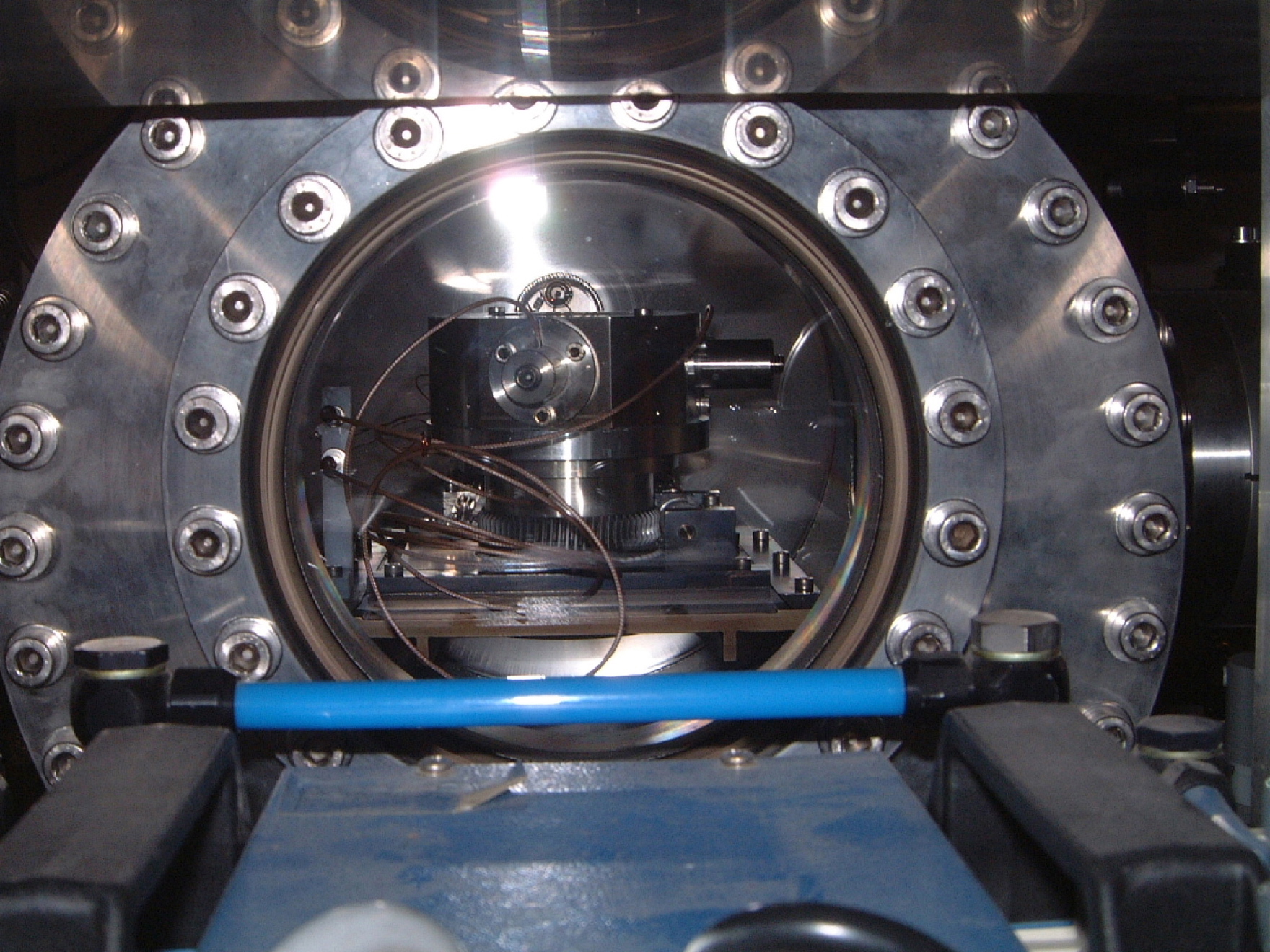

development of a two-stage axial symmetry collector for the recovery of residual charged ion beams (completed)

-

study of the production of secondary electrons in energy recovery for the production of neutral ion beams. (completed)

N-TOF :

-

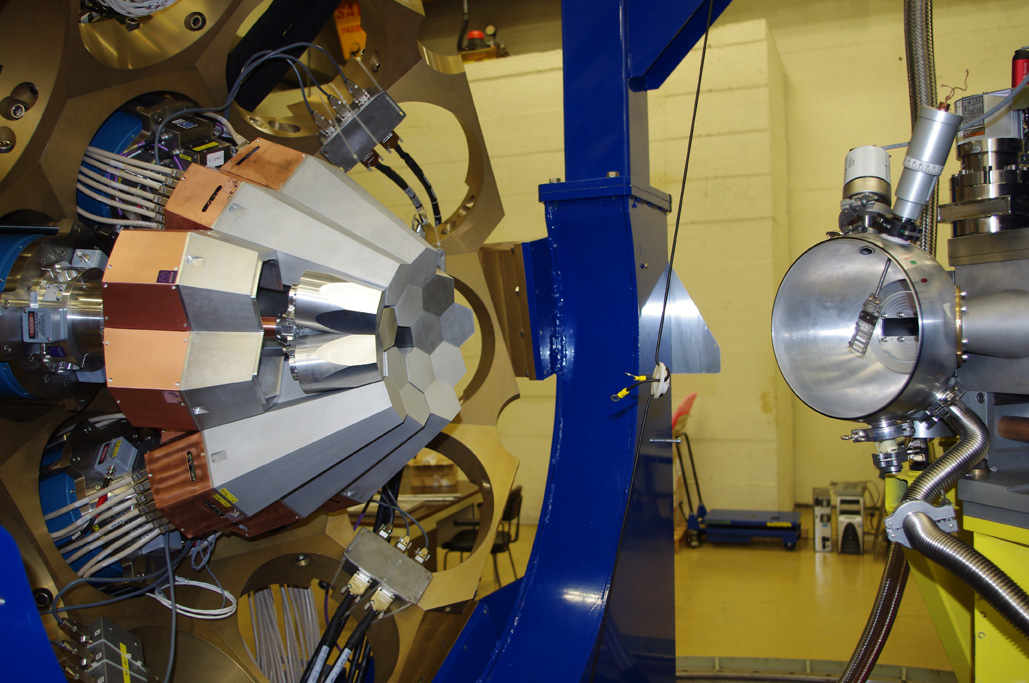

development of profile monitoring through microchannel plate and CCD imaging for neutron beams and charged particles (completed)

-

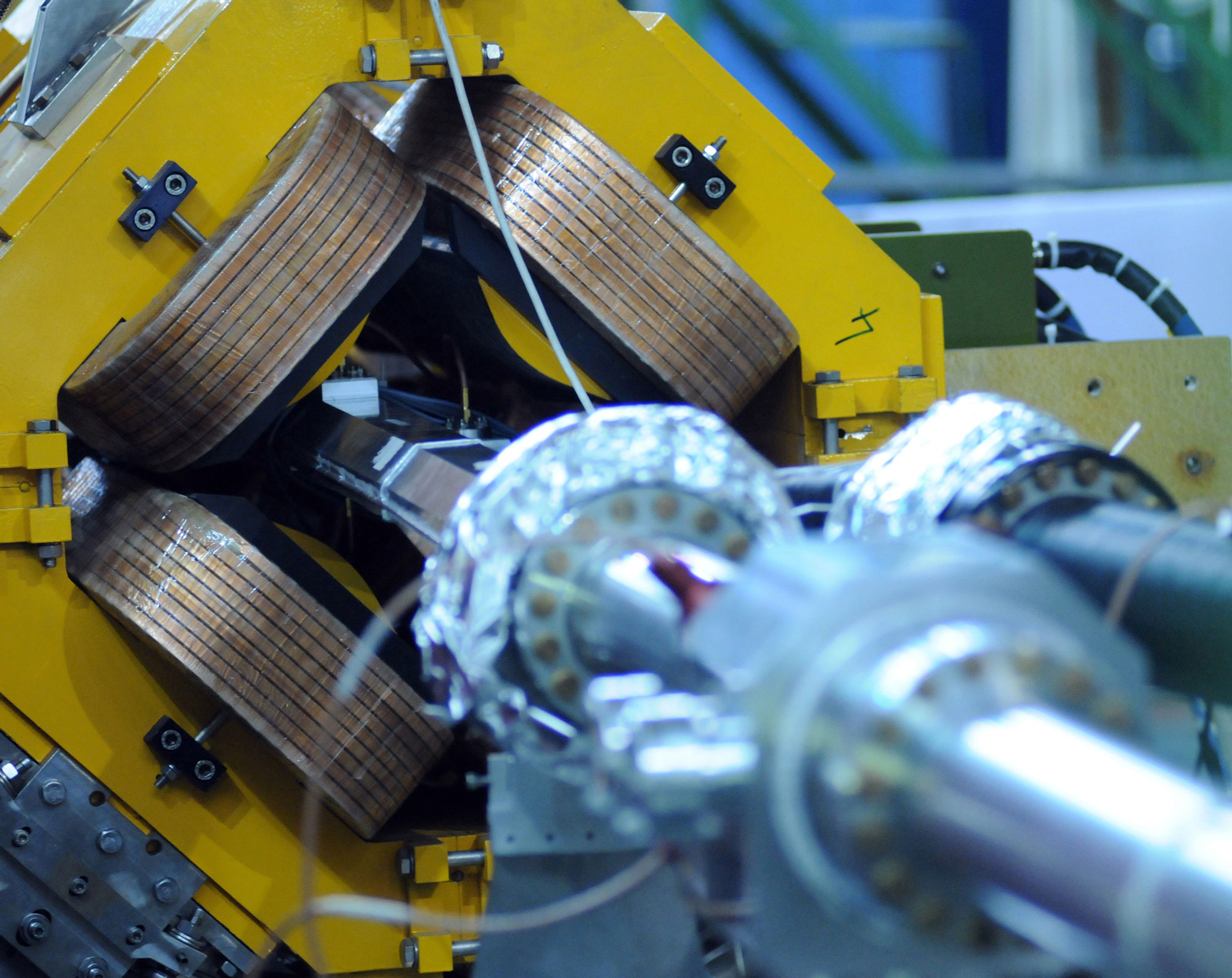

development of MPGD detectors for beam monitoring for linear proton accelerators (60-230 MeV) for hadron therapy (completed)

-

beam delivery system for linear proton accelerators (60-230 MeV) for hadron therapy (completed)

-

study of a 65 MeV proton beam transport channel for hadrontherapy applications (completed)

Instrumentation:

- high vacuum ion pumps

- residual gas analyzer

- electron gun with hollow cathode

- Mechanical workshop with 1 CNC machining center (HURCO brand) with 5 axes. XYZ working area, 1524 * 660 * 610mm3. Positioning accuracy +/- 0.005mm (University convection)

- Mechanical workshop with 1 CNC machining center (HURCO brand) with 3 axes. XYZ working area, 2134 * 864 * 762mm3. Positioning accuracy +/- 0.005mm (University convection)

Skills:

- simulation: beam dynamics for linear accelerators

simulation and development of test systems for "negative ion sources"

simulation and development of "high state of charge sources" test systems

development of beam profile monitoring detectors for neutrons and charged beams

development of gas detectors and electronics for beam monitoring for medical applications

simulation with Fluka, Geant4, MagBoltz, Garfield, ANSYS, COMSOL for detector design and simulation for beam monitoring for medical applications

construction of beam lines and reaction chambers: mechanical part of installation and low / high vacuum pumping, control of solenoid valves.

use of rotary, turbomolecular and cryogenic pumps.

high vacuum (LASA Milan course certification)