Laboratori Nazionali di Legnaro

Introduction to LNL accelerator machines

Projects:

The second accelerator installed in Legnaro is of the electrostatic type like the CN but has a terminal voltage of 2 MV. It is therefore smaller: the only experimental room houses the accelerator (which incorporates the source), the beam channels and all the measurement points.

In the mid-eighties, LNLs made a first leap in performance, in terms of energy of the accelerated ions, with the acquisition of a third electrostatic accelerator, of the Tandem-XTU type, from the company High Voltage Engineering (based in the United States ). The Tandem, much larger than the CN-7 MV and AN2000 accelerators, is based on a slightly different operating principle. The high voltage terminal (which in the case of LNL exceeds 14.5 MV of maximum electrostatic voltage) is positioned in the center and on the axis of a horizontal tank, in turn filled with insulation gas (SF6 sulfur hexafluoride) to a pressure of 7 atm.

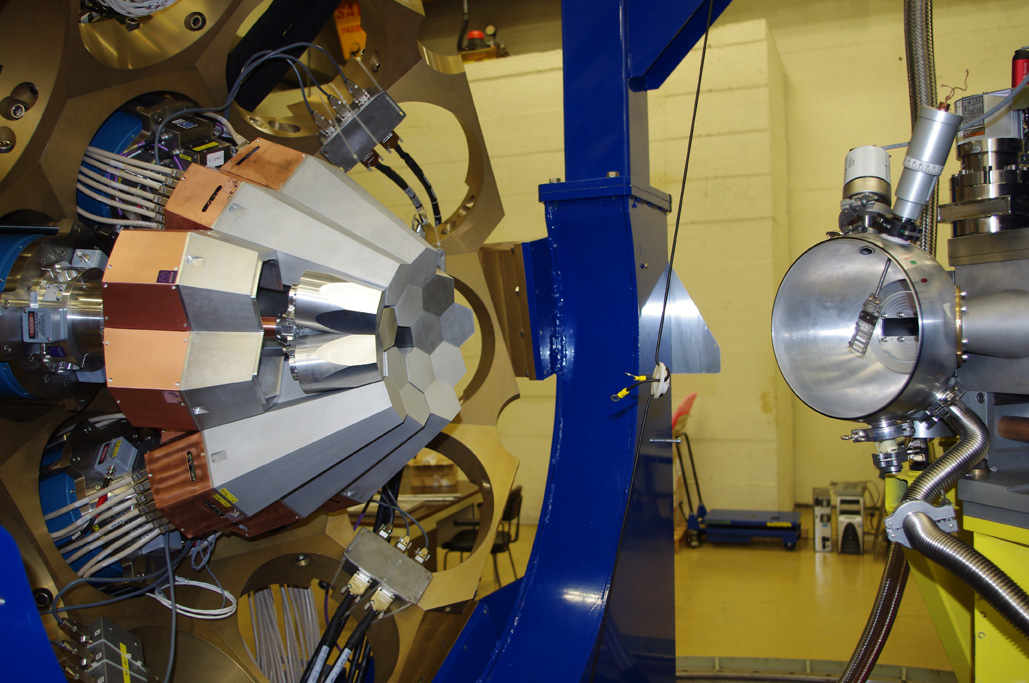

At the LNL, the ALPI linear accelerator (acronym for "Linear Accelerator For Ions") (Fig. 10, left) is located in a shed adjacent to that of the XTU tandem, and receives the beam through a transport line of dipoles and quadrupolar magnetic lenses and bunchers. It was designed entirely by LNL technologists and researchers and went into operation in the first half of the 1990s.

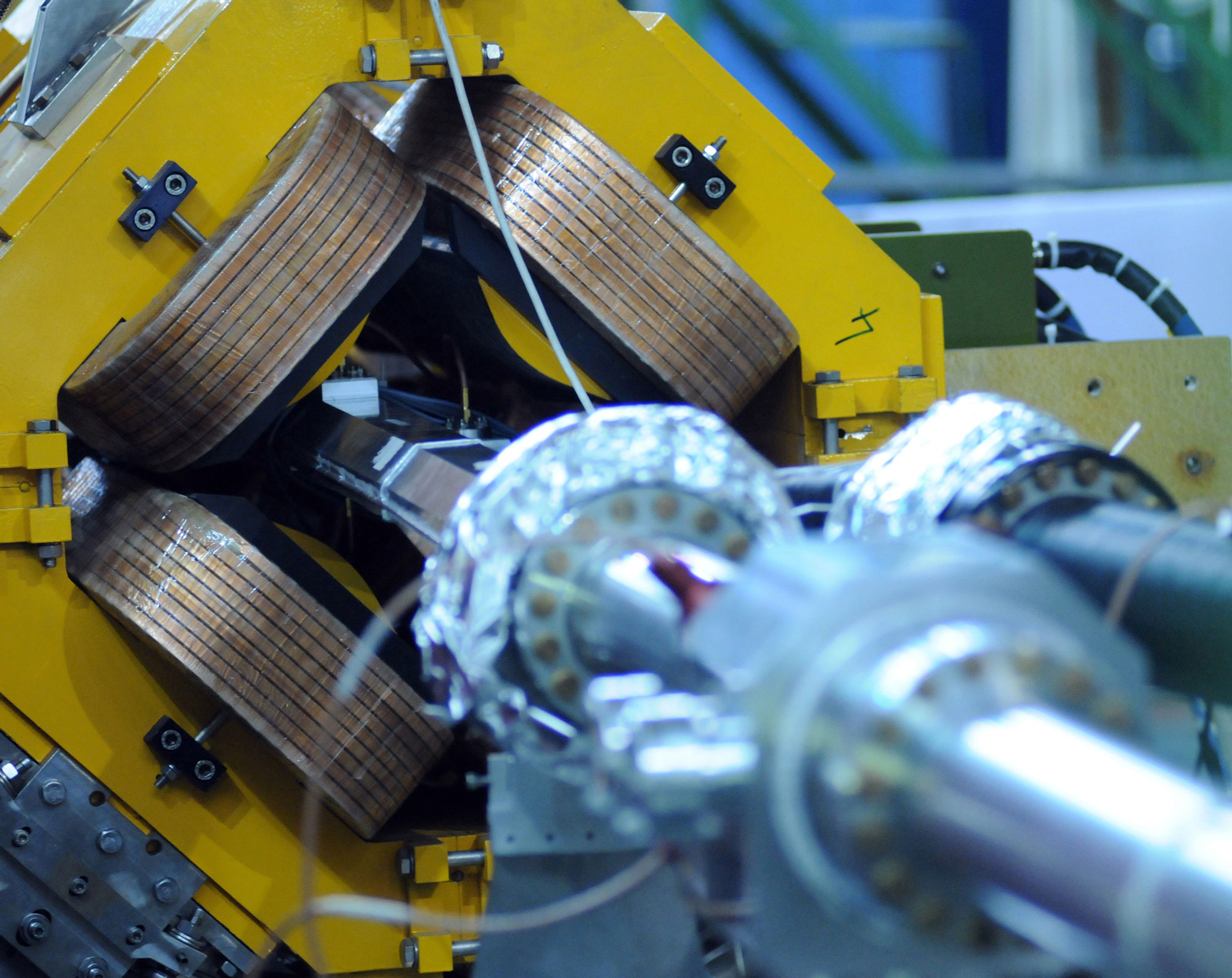

The PIAVE linac is called an injector because, unlike the Tandem, it can only operate jointly with ALPI, which receives the beam. It is located in the same building as ALPI, adjacent to the beam transport lines, to and from the experimental rooms closest to the Tandem. It too, like ALPI, is based on superconducting accelerating cavities and was designed entirely by LNL. It has been operational since 2004.

SPES-α foresees the acquisition, installation and commissioning of a high performance cyclotron with high output current (~ 0.7 mA) and high energy (up to 70 MeV), together with the related infrastructure for the accelerator and experimental stations

Surface treatments group (G. Keppel)

Projects:

- Development of innovative Nb thin and thick film cavities on Cu substrate both on 6 GHz and 1.3 GHz elliptical cavities

- Study of flow effect trapped in 6 GHz cavity

- QWR cavity coating for ALPI upgrade to LNL

- Development of technologies for the production of seamless elliptical accelerator cavities at different frequencies such as 600 and 800 MHz, 1.3, 1.5 and 6 GHz and QWR

Instrumentation:

- PVD and PE-CVD deposition systems of accelerator components (diode sputtering and magnetron sputtering)

- Facility for chemical and electrochemical polishing of accelerator components

- Facility for the measurement of QWR and elliptical resonant cavities up to 6 GHz, from 4.2 K up to 1.8 K.

Skills:

- Thin and thick film coating via PVD and PE-CVD of various superconducting and non-superconducting materials

- Characterization by XRD, SEM and superconducting properties of samples

- Chemical and physical surface treatments

- SRF measures

- Spinning from slabs or pipes

Group that takes care of ESS-DTL and IFMIF-RFQ

Projects:

- Development of high power (625 kW) and high current (125 mA) RFQs for the IFMIF-EVEDA project

- Development of medium power (200 kW) and medium current (40 mA) RFQs for the MUNES project

- Development of power couplers for the IFMIF-EVEDA project (200 kW CW)

- Development of power couplers for the MUNES project (125 kW CW)

- Development of the cooling system and frequency agreement for the RFQ cavity of the IFMIF-EVEDA project

- Development of the cooling system and frequency agreement for the RFQ cavity of the MUNES project

- Development of the local control system of the RFQ cavity of the IFMIF-EVEDA project

- Development of the DTL of the ESS project (90 MeV - 62.5 mA - 4% duty cycle)

- Development of the local control system of the DTL of the ESS project

- Development of the heavy water-graphite thermal moderator for the MUNES project

- Development of the Beryllium-Vanadium target prototype for the MUNES project

- Renewal of the local control system of the TRIPS source and extension of the same for the MUNES project

- Development of the control system for the transport of the beam in the ALPI-PIAVE acceleration lines for the SPES project

- Design and first development of the control architecture for the SPES project

- Development of magnets for low-energy transport lines for the MUNES project

- Study of normal-conductive magnetic systems with high resolving power

- Development of transport and handling lines for high intensity ions

- Development of fast emittance meters

- Development of high intensity ion sources (negative and positive)

- Development of Taylor-Langmuir detectors

- Multiphysics computational modeling

- Studies of theoretical models for sources and accelerators mentioned above, also with symbolic manipulation programs and / or innovative calculations

- Development of non-intercepting residual gas beam profile detectors

- Development of detectors to measure the temporal width of the bunch

- Study of models and algorithms for the analysis and tuning of four-vane RFQs

Instrumentation:

- Test stand 125 kW 352 MHz pulsed or continuous RF power

- Test stand 200 kW 175 MHz pulsed or continuous RF power

- Injector with proton beam 50 mA 80 KeV

- Facility irradiation with thermal neutrons (thermal component 92.5%) and contact fluxes up to 10 ^ 6 n / (s-cm ^ 2)

- Vector Network Analyzer with the following key features: 30 kHz-8 GHz band, low phase noise.

- Bench for dimensional control of precision mechanical components with the following instruments:

- Johansson Topaz 7 coordinate control machine with passive Renishaw PH10MQ head.

- Portable measuring arm with probe and optical sensors: ROMER 8730 with RS6

- FARO ION2 Laser Tracker System for fiducialisation and alignment of accelerator components.

- HPC server, 80 physical cores, for high-performance parallel-computing of complex interacting systems (dynamics of plasmas in low-energy and high-intensity magnetostatic lines via WARP software)

- Helmholtz coils for magnetization measurements

- Adixen asm He leak detector

- Measurement system of electric and / or magnetic fields in accelerating cavities using the bead-pulling technique

Skills:

- RF power amplifiers in the VHF and UHF bands based on tube technology

- RF power amplifiers in the VHF and UHF bands based on solid state technology

- Components for RF power applications in the VHF and UHF bands

- Dynamics of ion beams in linear accelerators

- Dynamics of proton and deuteron beams with high perveance in linear accelerators

- Sources and low energy lines of protons / deutons

- Bundle transport

- Alignment by laser tracker

- Radio frequency quadrupoles

- Drift Tube Linac

- Permanent magnets

- Dipolar correctors

- Beam position monitor

- Definition of the production cycles of mechanical components (definition of the material, thermal cycles, machining in machine tools)

- Characterization and tuning of the radiofrequency cavity

- 2D and 3D simulations of accelerating cavities and associated RF components

- Controls based on industrial solutions (PLC) and controls based on EPICS solutions

- Network architecture administration

- Mechanical design of components for normal-conductive accelerators. Use of ANSYS, NX, PC-DMIS, Calypso software for thermo-structural design, drafting, and metrological control according to ISO / ASME Y14.5 respectively. Metrological characterization of components for accelerators. Simulation of thermal cycles of vacuum brazing and Electron Beam Welding.

- Vacuum tightness test with helium on components subjected to high vacuum

- Ultra-high vacuum brazing.

- Interceptive and non-interceptive beam transverse profile diagnostics.

- Beam time profile diagnostics.

INFN-LNL Cryogenics Group

Projects:

- Revamping of LINDE TCF20 LIQUEFACTOR control system according to UNICOS-CERN standard (main cabinet design, PLC software and supervision)

- Revamping of the LINAC CRYOSTAT control system according to UNICOS-CERN standard (main cabinet design, PLC software and supervision)

- Revamping of the ALPI REFRIGERATOR control system according to UNICOS-CERN standard (main cabinet design, PLC software and supervision)

- Installation III TURBINE cryogenic cooler ALPI (company support, problem solving, testing)

- New ALPI turbine chiller III cooldown system (software rewrite and circuit changes)

- Repair and redesign of the auxiliary Cold Box for ALPI (liquid nitrogen dewar thermal leak problems solved to the outside, control system redone and old cabinet replaced)

- Redesign of SRFQ cryostat components (liquid helium line, sensors, safety valve discharge line)

- Design of new activated carbon towers for compression groups A and B

- Reposition of 2 cryostats for QWR resonant cavities from PIAVE to ALPI-LINAC

- Revamping of the PIAVE REFRIGERATOR control system according to UNICOS-CERN standard (main cabinet design in completion, PLC software development and supervision soon)

- Realization of a new control system for HELIUM RECOVERY and monitoring of impurities (main cabinet design in completion, PLC software development and supervision in completion)

Instrumentation:

- Cryogenic chiller helium ALPI (1200W @ 4,5K - 3900W @ 60-75K, 150g / s @ 16bara)

- Cryogenic chiller helium PIAVE (This email address is being protected from spambots. You need JavaScript enabled to view it., 525W @ 40-100K, 63g / s @ 13bara)

- Linde TCF20 liquefier, 20 liters / hour (40 l / h with LN2 precooling)

- High pressure helium gas recovery system (3 reciprocating compressors capacity 200Nm3 / h, delivery pressure up to 200bar, helium storage 32m3 @ 200Bar)

- Helium gas drying plant (3 automatic dryers, 3x60Nm3 / h 70 ° C dew point)

- Helium compression unit for ALPI cryogenic chiller (4 vi te, flow rate 95g / s, 65g / s, 2x55g / s @ 16bara)

- Helium compression unit for PIAVE cryogenic chiller (screw compressors 63g / s @ 13bara)

- Auxiliary Cold Box for cooling the LINAC cryomodule screens in case of failure of the main cold box

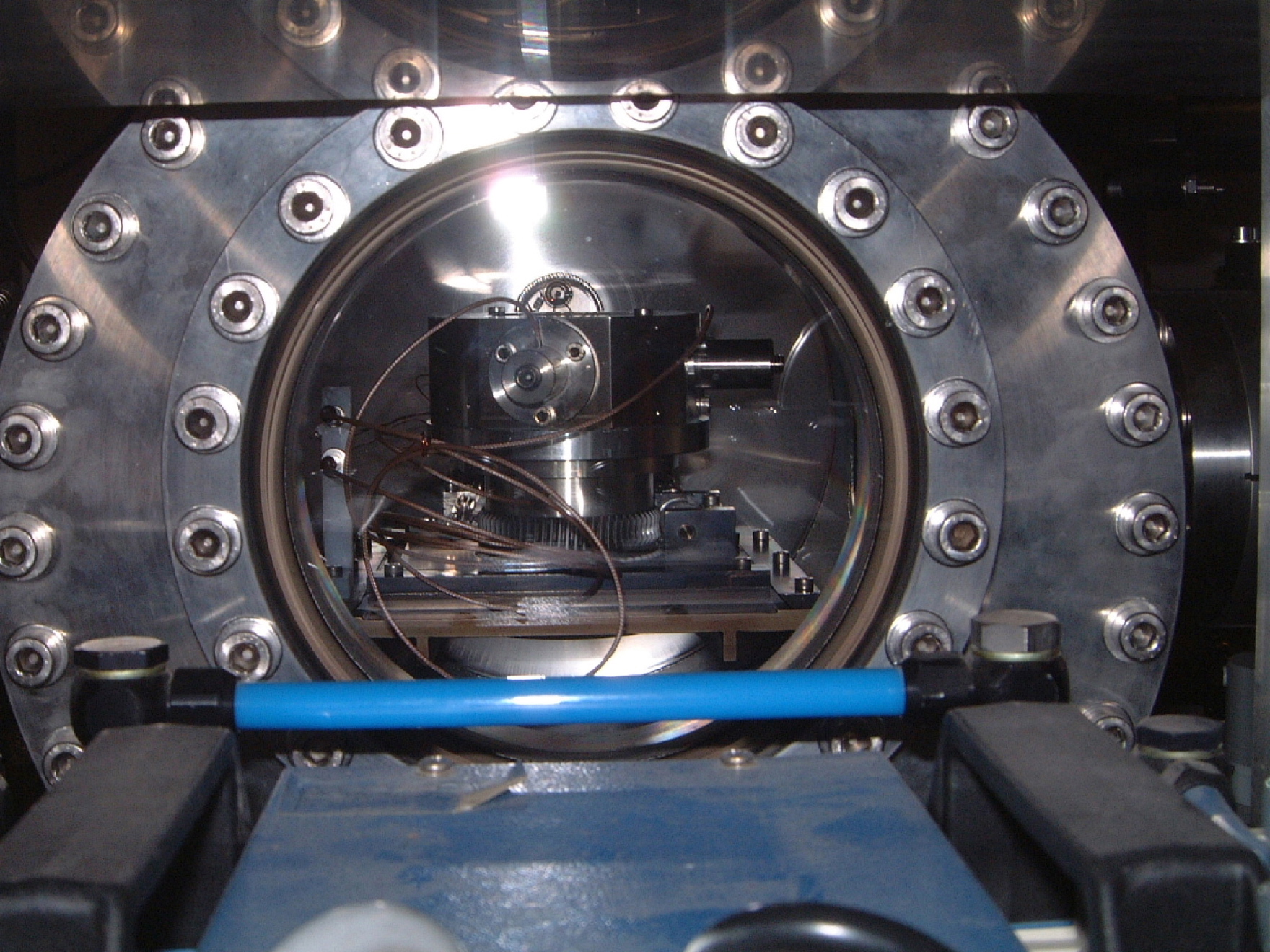

- 1 cryostat for resonant cavities SRFQ (2 superconducting quadrupoles in Nb bulk)

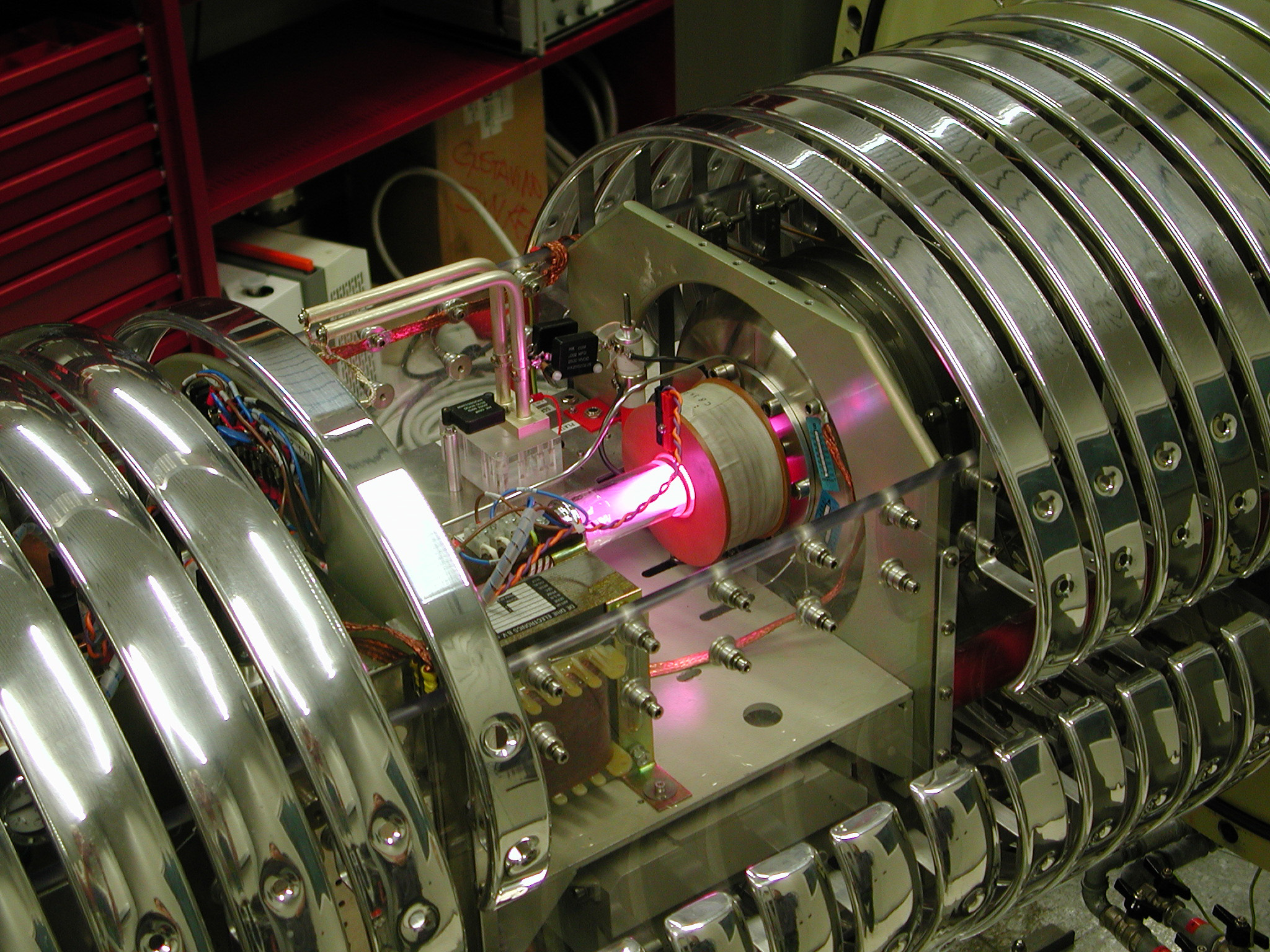

- 22 cryostats for QWR resonant cavities (quarter wave cavity)

- Automated liquid nitrogen distribution line for low beta cryostats

- Cryostat maintenance laboratory for QWR cavities

- Leak detection instrumentation: leak detector

- Leak detection instrumentation: helium sniffer

- High vacuum groups for cryogenic lines

- High vacuum units for cold box chillers (groups with primary diffusion pump)

- Semi-automated helium recovery system

- Server for cryogenic plant supervision

Skills:

- Operation with the Air Liquide cryogenic chiller (ALPI)

- Operation with cryogenic chiller and Linde (TCF50)

- Operation with the Linde TCF20 liquefier

- Operation on LINAC accelerator cryomodules

- Operation with automated liquid nitrogen cryogenic purifier for helium gas

- Operation with the ALPI auxiliary Cold Box

- Liquid helium dewar filling (250l-500l-1000l-3500l)

- Search for vacuum lines (with leak detector) and lines under pressure with helium sniffer

- Design and preliminary design of automation panels revamping projects for UNICOS - CERN standard control systems

- Creation and design of automated systems (PLC and SCADA)

- Maintenance of cryogenic and liquefier coolers (replacement of cryogenic turbines, replacement of filter cartridges, replacement of sensors, adjustment of valve positioners, electronic instrumentation maintenance)

- Compressor unit maintenance (replacement of oil separator cartridges, replacement of electric motor, replacement of activated carbon, replacement of cycle compressor oil, washing, maintenance of sensors and control valves, maintenance of pneumatic and hydraulic circuit)

- Cryostats maintenance for QWR and SRFQ cavities

- Maintenance of helium dryers to remove moisture from helium

- Maintenance of electrical panels (automation)

- Cryogenic valve maintenance

- Schneider PLC programming (Unity software)

- WinCC_OA SCADA programming

- Basic use of Laser Traker

- Electronic instrumentation repair (temperature monitor, operator panels, liquid helium level monitor, control valve positioners, etc.)

- Repair of various components (actuators, solenoid valves, overhaul of pressure regulators, valves, construction of connected pipes, etc.)

LNL - Cyclotron Group

Projects:

- Development and prototyping of an electrostatic accelerator with optical power supply

- Development of trapping and cooling systems for ion beams by means of buffer gas

- Development and design of RF bunching systems for cyclotrons injection optimization

- Development of particle beam pulsing systems with solid state technology

- Development of high-power beam transport lines

- Preliminary study and design of '' ironless '' type superconducting compact cyclotrons for the production of high power beams

- Preliminary study and design of resistive cyclotrons for high power beams

- Study of ADS systems (Accelerator Driven System) for subcritical reactors

- Instrumentation

- RF dummy load system for power amplifier tests (up to 80 kW)

- Skills

- Beam dynamics for high power cyclotrons

- Optics and beam transport

- Low energy ion beam dynamics and cooling techniques by means of collisional models

- Operations of cyclotrons and transport lines with high power proton beams

- Modeling and design of electromagnetic systems in the field of accelerators (magnets, RF cavities, ...) with FEM codes and multiphysics

- Modeling and design of devices based on permanent magnets (Wien Filter, Energy Selector System)

- Mechanical design

- Vacuum and ultra-high vacuum techniques

- High precision laser techniques

- RF power amplifiers

LNL - Group Controls and RF

Skills:

- Development of digital and analog electronic circuits

- Testing and debugging of digital and analog electronic circuits (including manual interventions on SMD PCB)

- Advanced use of laboratory instruments (among the main ones: Digital Oscilloscopes, Power Supplies, Multimeters, VNAs, Signal Generators, Function Generators, Frequency Counters, Bolometers) including programming and automation of measurements via standard LXI protocol.

- Development of systems based on programmable logic devices (FPGA CPLD) and embedded systems and related development tools (VHDL programming)

- Automatic control systems.

- RF power technology and related control systems.

- Measurements and characterization of normal conductive and superconductive radiofrequency resonant cavities.

- Development of Linux Kernel drivers and modules

- Programming and at low and high level with different programming languages (C, C ++, Java, Javascript, PHP, Python)

- System-level management and configuration of computers based on Linux and Windows systems

- Management and configuration of Ethernet network infrastructures and related services (among the main ones: DHCP, DNS, Firewall, NFS, SAMBA, NTP, VLAN, WiFi, ZFS, LVM, automatic data / database replication and backup)

- Management and configuration of virtualization and para-virtualization systems based on Proxmox, QEMU / kvm and Docker.

- Development, configuration and management of systems based on standard models of AI and computer vision (classifiers, object recognition, object re-identification)

- Development, configuration and management of control systems based on EPICS framework

- Development, configuration and management of graphic interfaces for EPICS control systems

- Development, configuration and management of control systems based on PLC Schneider and SIEMENS and related SCADA.

- Implementation of data acquisition systems in the field of experimental physics and diagnostics of accelerated particle beams.

- design and management of magnetic lenses for accelerators and management of the relative power supplies

- electrical / hydraulic systems on the machine accelerators

- Implementation of access control systems for accelerators.

- design and development of induction furnaces for ECR.

- Sizing of electrical machines.

- PILZ safety controllers configuration.

- Mechanical and electrical CAD design.

- Electrical design of LV and signal networks.

- Assembly and wiring of automation systems.

- Pneumatic design.

- Warehouse and inventory management.

LNL - ISOL Group

Projects:

- Development of surface ionization sources for the ISOL system for the SPES project and ADIGE initiator

- Development of plasma ionization sources for the ISOL system for the SPES project and ADIGE injector

- Development of laser ionization sources for the ISOL system for the SPES project

- Development of high power targets (12 kW) in UCx for the SPES project

- Development of automatic handling systems (AGV) for targets / activated sources of the SPES project

- FEM computational modeling for thermostructural calculations of high power targets

- Development of innovative high temperature ceramic sources with 3D printing

- Development of innovative sources of high temperature composite materials with 3D printing

- Development of 50 kW beam dump for SPES cyclotron proton beam

- Development of a time-of-flight mass spectrometer

Instrumentation:

- Front end for ionization tests, 40 kV extraction and beam transport for the SPES project

- Wien filter for ion beam mass selection tests for the SPES project

- Emittance meter for transversal beam emittance measurements

- Energy spread meter for longitudinal beam emittance measurements

- Thermal characterization furnace for emissivity measurements of various materials

- Carburetor furnace for SPES and R&D standard target discs

- Chemistry laboratory for manufacturing target discs in various materials (e.g. Lanthanum Carbide)

- Low rep rate (10 Hz) DYE tunable laser systems for resonant laser photoionization tests

- offline

- High rep rate (10 kHz) solid state (TiSa) tunable laser systems for online resonant laser photoionization for the SPES project

- UCx laboratory for the study and manufacture of Uranium carbide discs

- Time-of-flight mass spectrometer

Skills:

- Mechanical design

- Thermomechanical design

- Multiphysics design

- Vacuum systems design

- 2D / 3D cad drawing

- Resonant laser photoionization systems

- Laser ablation systems

- Dynamics of low energy beams

- Electrostatic elements of beam transport

- Beam transport / mass selection magnetic elements

- Electronic systems design

- Mechanical development of diagnostic tools (faraday cup and beam profiler) for high energy proton beam (40 MeV)

- PLC control systems design and programming

- Beam transport simulation using SIMION®

- Beam transport simulation using TRACEWIN®

- Transport simulation and iteration with matter of elementary particles and nuclei for power deposition, production and activation studies using FLUKA® and SRIM®